Introducing Radiant Wood Track

Product Highlight featuring Radiant Wood Track. MrPEX Systems now offers a Radiant Wood Track System for the use of 3/8″ PEX tubing to minimize additional floor height. The MrPEX Radiant Wood Track comes in three standard panels, Run Panel, Turn-Around Panel, and Manifold Panel. Each panel is 12″ x 48″ x 5/8″ and are marked for easy and optimal cutting to fit any layout. This is a great product to combine hardwood floors with radiant floor heating!

Introducing F1960 Cold Expansion Fittings

Product Highlight featuring F1960 Cold Expansion Fittings. MrPEX Systems now carries a wide variety of Lead Free Brass and PPSU Fittings along with PEX Rings. Sizes are 1/2″ through 2″.

Introducing Pre-Insulated PEX-a Tubing

MrPEX Systems is happy to announce that we now offer Pre-Insulated PEX-a Pipe. We should have what you need on hand and cut to length for all project sizes. Please call your local MrPEX Representative with any questions regarding this product.

Click on the link below for more information…

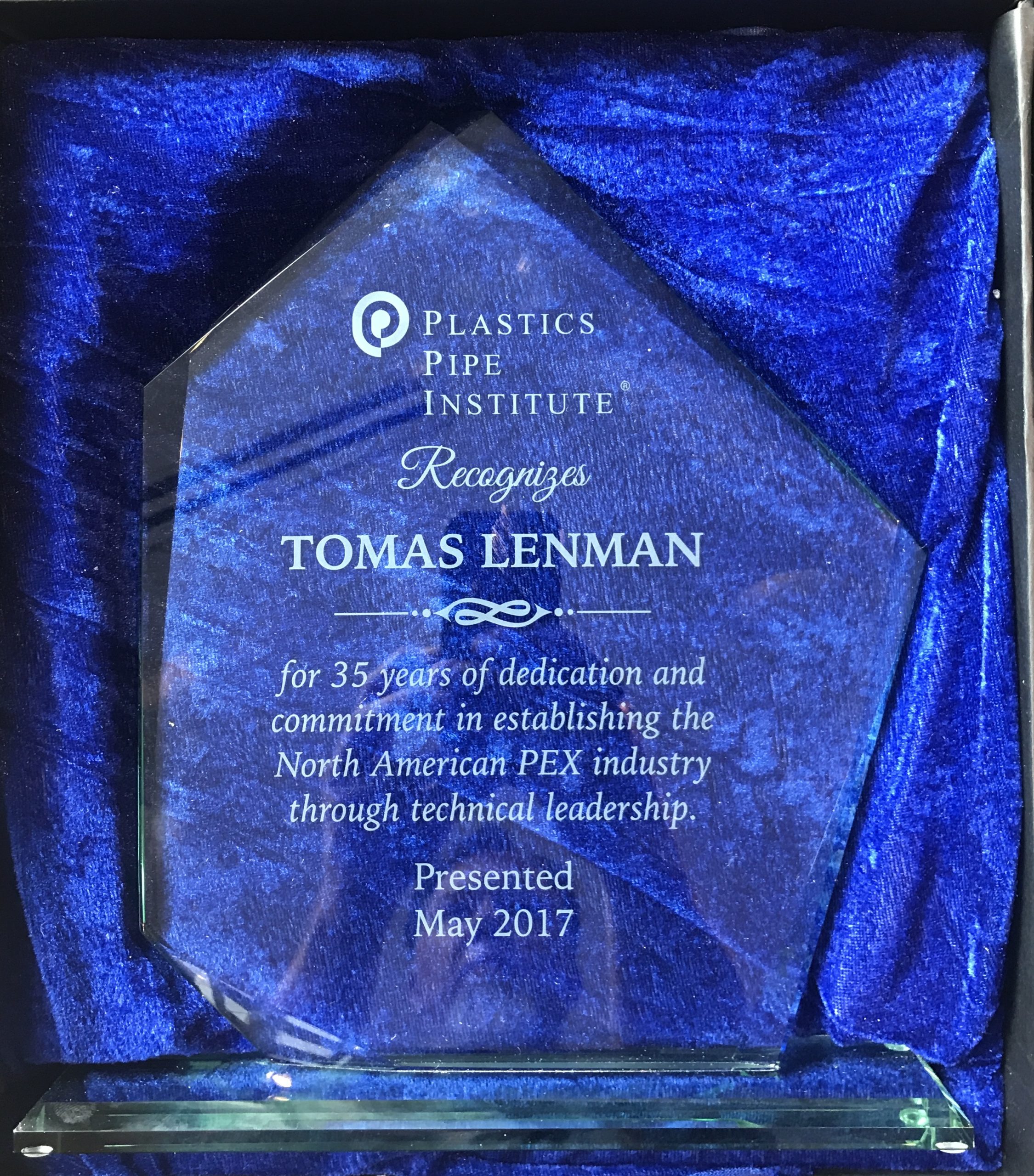

Tomas Lenman Receives Prestigious PPI Award

May 2017; Tomas “MrPEX” Lenman was recognized by PPI ( Plastics Pipe Institute) with a 35 years of dedication and commitment in establishing the North American PEX Industry through technical leadership award. Although Tomas wasn’t able to accept this award in person, he was happy to pose for a picture when it was handed to him! Tomas, now retired, spends his summers in Sweden relaxing at his lake-place. When not there, he and his wife enjoy spending time traveling together! Tomas is a true inspiration of perseverance and accomplishment and will be missed in the PEX industry!

May 2017; Tomas “MrPEX” Lenman was recognized by PPI ( Plastics Pipe Institute) with a 35 years of dedication and commitment in establishing the North American PEX Industry through technical leadership award. Although Tomas wasn’t able to accept this award in person, he was happy to pose for a picture when it was handed to him! Tomas, now retired, spends his summers in Sweden relaxing at his lake-place. When not there, he and his wife enjoy spending time traveling together! Tomas is a true inspiration of perseverance and accomplishment and will be missed in the PEX industry!

Tomas Retires

Tomas “Mr.PEX” Lenman, Owner & Founder MrPEX® Systems, Retires.

Tomas “MrPEX” Lenman

In 1971, when Tom Lenman began his career as a development engineer at Wirsbo in Sweden, he never imagined he would stay in the same trade for a lifetime. After learning to build airplanes at the Royal Institute of Technology, his interest shifted to development of PEX Tubing for hot water applications. Virtually a new arena for plastics, it required many months of research to find suitable material designs, additives, optimizing properties, etc. Even more challenging was getting the material approved for its intended applications. Authorities were skeptical and required extensive testing. Since European cooperation between countries was only an idea at that time, every country needed to be approached separately for approval.

“Willis Carrier is often called the “father of modern air conditioning.” In the same regard, Tomas Lenman should be credited as the man who introduced North America to PEX tubing starting back in the 1980s.

At that time, PEX was viewed somewhat skeptically by many heating pros, including me, who thought that any tubing used in a heating system had to be metal. Tomas’s efforts to educate North American about the technology and quality control involved in producing PEX tubing changed this attitude, and cultivated a North American market that now measures annual sales of PEX by the billions of feet.

Over the years Tomas has graciously helped me with specific inquiries about PEX. I have great admiration for his technical understanding and factual unbiased responses to my questions.

Tomas, you will also be “Mr Pex” in my mind. My sincerest thanks for the outstanding contributions you’ve made to the North American heating, cooling, and plumbing industry.” – Sincerely, John Siegenthaler

At the same time, Shell Chemical invented a new Polymer in the United States: Polybutylene. After early success in the US, they approached the European market. PEX and PB were bidding the approval of committees in several different countries. For PEX (and Wirsbo), Tomas was the representative, while Shell Chemical normally came to meetings with several constituents, under the oversight of Steve Pregun. Steve would typically introduce Tomas as “Mr. PEX” to new colleagues and meeting attendees. The nickname stuck and has followed Tomas ever since.

By the early 1980’s, Tomas was working on the US PEX standards, now known as ASTM F876 & F877. Meetings took place 3 to 4 times per year. Shell Chemical had succeeded in developing an ASTM standard specification for Polybutylene (PB) a few years earlier. At this point, they had 6 strong Polybutylene tubing manufacturers attending the PEX standardization committees. Tomas had some support from PE raw material manufacturers and professional code developers, but realized the PB majority would be able to raise unlimited objections and delay the PEX standard indefinitely. The European and International (ISO) standards had different ways to evaluate and predict long-term strength of Plastic Pipes – compared to US standards (read ASTM D 2837). Shell’s own data, as provided to ISO and several European committees, clearly displayed a “knee” in the long-term strength data at higher temperatures, (a “knee” indicates a clear point of extrapolated failure) as well as independent data from European testing institutes (including such tests paid by Wirsbo). With this data presented to ASTM committees, they would have no choice, but to change the pressure rating or the wall thickness of the Polybutylene pipes (with a lot of installed PB Tubing becoming disapproved). Tomas showed the data to Steve Pregun and spoke of his intention to start a new ASTM project to revise the PB stress rating. After negotiating, the two ASTM PEX Standards were published 6 months later in the fall of 1984. Tomas had already arrived in the United States in August of that same year to start the subsidiary Wirsbo Company.

“I was in business for a year and a half in December 1990 when Tomas Lenman invited me to travel to Sweden with a group of industry writers to be a part of Wirsbo’s Ten Times Around The World celebration. They had sold that much PEX pipe by the end of that year, and Thomas Lenman had played a large part in its development.

I knew little about radiant heating that year, other than what I had gleaned from my old heating books, and those systems were of copper tubing, not this remarkable new plastic that Tomas Lenman was introducing to the United States.

We toured a bit of Stockholm on that trip and then continued on by bus to the celebration, where I listened to Tomas Engel, the man who had invented PEX. I had never heard of him at the time and I smile now at the thought that I once was in the same room with that brilliant man.

Tomas Lenman moved on to other challenges and other companies as the years went by. He always excelled. Along the way, I had many questions for him over the years, and many of those questions arrived wearing boxing gloves. You see I was a brash young man back then and I had not yet learned the habit of just shutting up and listening to those who were older, and in Tomas Lenman’s case, certainly smarter than I was. I wish I had been a better student for him.

So as you prepare to retire, I say thank you, sir. Thank you for your patience with me. And thank you for all that you’ve done for this wonderful industry.” –Dan Holohan

Tomas Lenman can also add “author” to his list of accomplishments. His book “Water and Pipes” has been published in three languages and the US version was distributed twice in 1984-85. The  book mirrored what he learned on the subject up to that time. Trade magazines gave it fair exposure and gave Wirsbo name recognition. In the late 80’s a “Wirsbo System” was more known to the trade than “Under Floor Heating System”. The content of the book is available on the MrPEX® website at www.mrpexsystems.com/water-and-pipes. In 1986, they began publishing “World of Wirsbo” 4 times a year. It was about successful radiant heating projects and provided the nuts and bolts on how they work.

book mirrored what he learned on the subject up to that time. Trade magazines gave it fair exposure and gave Wirsbo name recognition. In the late 80’s a “Wirsbo System” was more known to the trade than “Under Floor Heating System”. The content of the book is available on the MrPEX® website at www.mrpexsystems.com/water-and-pipes. In 1986, they began publishing “World of Wirsbo” 4 times a year. It was about successful radiant heating projects and provided the nuts and bolts on how they work.

In the early 90’s Wirsbo owned close to 50% of the radiant floor heating market share; the market penetration increased rapidly and several new system suppliers entered. HRHA (Hydronic Radiant Heating Association) was formed, but only survived a couple years. Tomas could not agree with the majority: to downgrade the importance of oxygen barriers on polymer tubing for heating. Wirsbo only supplied tubing with Oxygen Diffusion Barrier to the market, but some competitors did not. A huge amount of European experience and research was challenged and dismissed by many for a few years. Some of you remember trade magazine articles like “Looking for Elvis” (looking for systems with corrosion problems due to oxygen in the systems). Fortunately, “Elvis” was soon found and only a limited number of systems suffered from the bad design.

At the time, Finland based Uponor, was producing plastic pipes for cold water distribution, sewer applications and gas distribution. Uponor acquired Hewing (Germany) and Wirsbo (Sweden) in 1988, the two dominant manufacturers of PEX Tubing in the Western hemisphere. Over the next decade, Uponor continued acquisitions of companies active in hot water distribution, but also sold off its interests in traditional (cold water or gas) plastic pipes applications. A total transformation of product lines took place, bringing strength to their trade names in the plumbing and heating field. Their marketing strategy was Multi-brand, Multi-channel Distribution, which was successful for many years. Around 2006, it was astonishing when the group decided to unify operations under the single trade name, “Uponor.” Well established trade names are considered valuable assets and often booked on corporate balance sheets. Trade names such as Wirsbo, Velta and Polytherm were scrapped in favor of the virtually unknown Uponor (at least in North America).

In the fall of 2000, Tomas learned that the LK Group in Sweden had hired Lennart Agren to setup a new PEX production plant. Tomas met with Lennart and LK Group at the ISH show in Frankfurt, March 2001. The combination of a fast production process, adding polymer layers (such as oxygen barriers, etc.) and curing to optimal crosslinking in line, while at the same time (partly) orienting the molecules around the perimeter of the tubing resulted in a winning concept; a fast PEX (a process resulting in a tubing with exceptional flexibility and still stronger than most). Tomas gained the exclusive distribution rights to the US market, terminating his then current employment (Roth USA), and started MrPEX® Systems in June 2001. After a year of hard work and preparation, the product line launched in the spring of 2002.

Once again, contenders tried to delay and stop the introduction. This time it was not Polybutylene competition, but existing PEX manufacturers who argued that MrPEX® Tubing should meet additional testing requirements, such as testing the degree of molecular orientation in the tubing. Since Tomas knew the important crucial parameters for other PEX manufacturing processes that lacked prescribed testing, the extra requirements were dismissed and MrPEX® was approved.

Tubing in Earthquake safe high voltage transformers: ABB (Asea / Brown Bowery) used water to chill huge transformers. Flexible 2” PEX Tubing, pre-formed in an S-shape, led the water to and from the hanging transformers, making the construction earthquake- safe. As he retires and looks back at his professional life, Tomas says he feels satisfaction. “It has been a great journey developing the PEX material, working on its applications and getting it approved for plumbing and heating in many countries. At the same time the most gratification in life is received through interaction with people. Thank you, PEOPLE! Thank you for listening, thank you for friendship, thank you for believing (in PEX and in me), and most of all, thank you for purchasing MrPEX® products!”

Did you Know?

Did you know there are many other applications for PEX? A few examples are:

Ski-soles: in Cervinia, Italy, there is a straight downhill track called “The Flying Kilometer” where competitions take place every year. A new world record was set there in 1976. The ski’s soles used were made of PEX Tubing, slit open and chilled down flat. More than half of the downhill medals at the Innsbruck 1976 Winter Olympics went to Wirsbo’s PEX soles.

Tubing for blood: A major dialysis machine manufacturer used custom pre-formed 1/4“PEX tubing between the machine’s different chambers. The price per weight was higher than that of gold.

Tubing in Earthquake safe high voltage transformers: ABB (Asea / Brown Bowery) used water to chill huge transformers. Flexible 2” PEX Tubing, pre-formed in an S-shape, led the water to and from the hanging transformers, making the construction earthquake- safe.

MrPEX® Systems & LK Pex

From the left: Sales Director Theresa Gunnergren, Managing Director Mats Larsson, Production Manager Jyrki Hölsö cuts the band since he has been along since the start 1998, representative of the owners of the LK Group Claes Behm.

Opening Ceremony of new production facility.

On September 3rd, LK Pex unveiled their brand new state-of-the-art production facility in Ulricehamn, Sweden. LK Pex is the sole supplier of PEX-a tubing for MrPEX® Systems who has the exclusive rights for the USA market. MrPEX® Systems offers Radiant Heating/Cooling, Snow Melting, and soon PEX-a Plumbing systems, has been selling LK Pex tubing in the USA since its inception in 2002.

The new 110 000 ft² production facility, only a few miles away from the previous location, is now open with several additional production lines increasing capacity to 263 million feet pipe/year. The new building, also owned by the LK Group might be the most energy efficient factory in Europe. A long term contract was established with a local district heating company to install a heat recovery system that captures the heat generated by the extruders to help with both heating the building, as well as allowing the waste energy to be sold back to the local community. It is estimated that LK Pex may be able to supply enough waste energy to heat the whole industrial park where they are located. Additionally, the entire building is equipped with LED-lighting, which reduces the lighting energy usage by 70%. “A significant step in reducing energy use, cost, as well as saving the environment. In designing this new production facility, we aimed to learn from past success, plus leveraging all available new technology to improve all aspects of the building and production process to the best of our abilities” says Mats Larsson, Managing Director at LK Pex. Additionally, as a strategic move, LK Pex secured the rights to buy the adjacent properties for future expansions.

Present at the opening ceremony were members of the owner family, local politicians, members of the boards within the LK Group, and Managing Directors from all companies within the LK Group.